| Sign In | Join Free | My ecer.com.ru |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My ecer.com.ru |

|

Brand Name : Zhengde

Place of Origin : CHNIA

MOQ : 1tons

Price : negoiate

Payment Terms : L/C,T/T

Delivery Time : as Required

Packaging Details : Customer settings

Model NO. : ZD-PPGI

Application : PPGI

Edge : Slit edge

Stock : Stock

Material : Dx51d,Dx52D,Dx53D,Dx54D,S250gd,S350gd,S550gd

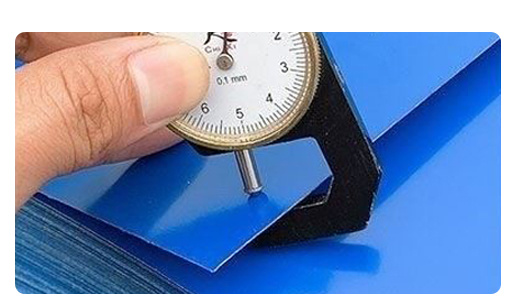

Thickness : 1mm-30mm or as Required

Width : 10mm-3000mm, as Required

Roll Weight : 0.5t-25t

Custom Made : Yes

Custom Cycle : 7-15 Days

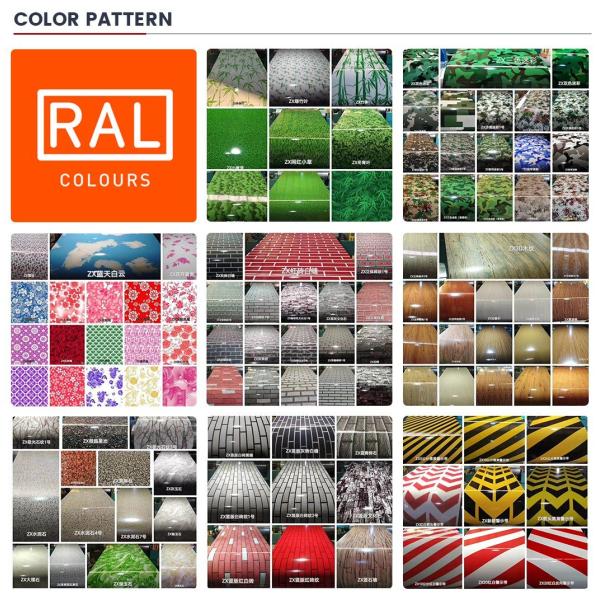

Color : Standard Red,Blue,White,Grey ,Ral Color

Surface : Hot Dipped Galvanized, Prepainted

Coating Type : PE/SMP/HDP/PVDF

Zinc Coating : 30-275G/M2

Processing Services : Welding Punching Cutting Decoiling

Production : 500 Tons/Month

HS : 7210490000

Tolerance : -/+1%

Transport Package : Export Standard Package/as Request

Specification : According to customer requirements

Trademark : zhengde

Origin : China

HS Code : 7210490000

Supply Ability : 30000 Tons/Month

After-sales Service : PPGI Steel Coil Endless Service

Warranty : According to The Use Environment

Standard : ASTM, JIS, GB, AISI, DIN, BS

Certification : ISO, RoHS, IBR

PPGI (Pre-Painted Galvanized Iron) Steel Coil is a high-performance material featuring a galvanized steel base coated with a layer of protective paint. The coating provides excellent corrosion resistance, weather resistance, and durability. PPGI steel coils come in a wide range of colors, offering versatility for various design requirements while ensuring long-lasting performance.

| Location | category | value | |||||

| Executive standard | National standard | GB/T12754-2019 | |||||

| American Standard/European Standard | ASTM A792M | ||||||

| Cold rolled substrate | Width specification | Cold rolled substrate thickness | Including metallized layer, the thickness after painting | Label thickness | |||

| 1200mm | ≥0.41mm | ≥0.46mm | ≥0.45mm | ||||

| Size deviation | Width tolerance | Upper deviation +4mm | |||||

| Lower deviation 0 | |||||||

| thickness | Upper deviation +0.05mm | ||||||

| Lower deviation 0 | |||||||

| Yield Strength | >300MPA | ||||||

| tensile strength | 270-500MPA | ||||||

| elongation after break | More than 20% | ||||||

| Steel coil inner diameter | Standard: 508mm,Except for other agreements | ||||||

| metal coating | alloy composition | AlZnMg or galvanized AlMg | |||||

| Total Weight of Plating Both Sides (Outside/Inside) | 150g/ (75/75 or 85/65) | ||||||

| Neutral salt spray test | The surface of the board (without passivation, anti-fingerprint and other treatments on the surface) has a neutral salt spray test of more than or equal to 2500 hours, and there is no red rust on the surface. | ||||||

| When the salt spray test on the wound surface (end surface) is greater than or equal to 1200, there is no red rust on the surface. | |||||||

| PPGI paint | PE coating structure standard (μm) | Paint structure | 2/1 | outside | ≥25 | ||

| Inside | ≥7 | ||||||

| pencil hardness | Not less than HB | ||||||

| Specular Gloss of Topcoat | Glossiness of finish paint mirror surface: ≥40 degrees | ||||||

| T bend value | 2T | ||||||

| Impact energy | Not less than 9J | ||||||

| Neutral salt spray test | Greater than or equal to 1500h without bubbles | ||||||

| UVB-313 | greater than or equal to 700h | ||||||

| PPGI use environment | humidity | 20% to 90% | |||||

| temperature | Min -45°C, Max 43°C | ||||||

| unit ammonia | <30ppm | ||||||

| unit carbon dioxide | <7000ppm | ||||||

| unit oxygen | 21% | ||||||

| unit hydrogen sulfide | <5ppm | ||||||

|

|

0.5mm PPGI Steel Coil with Excellent Corrosion Resistance Hot Dipped Galvanized and Customizable Colors Images |